Technologies

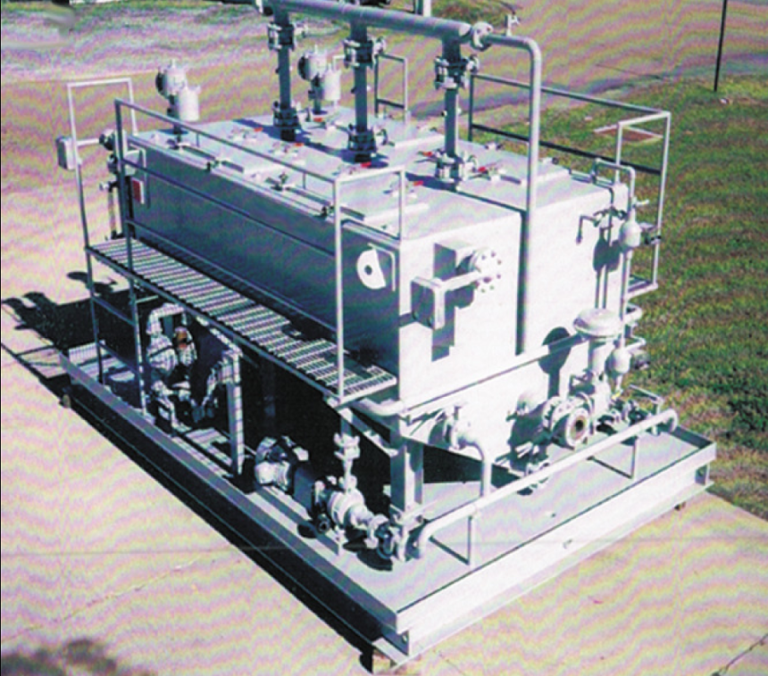

OIL WATER SEPARATORS

Designed according to API 421, Oil/Water Separators combine state-of-the-art separation, skimming and sludge transport technologies into a highly efficient primary oil separation device.

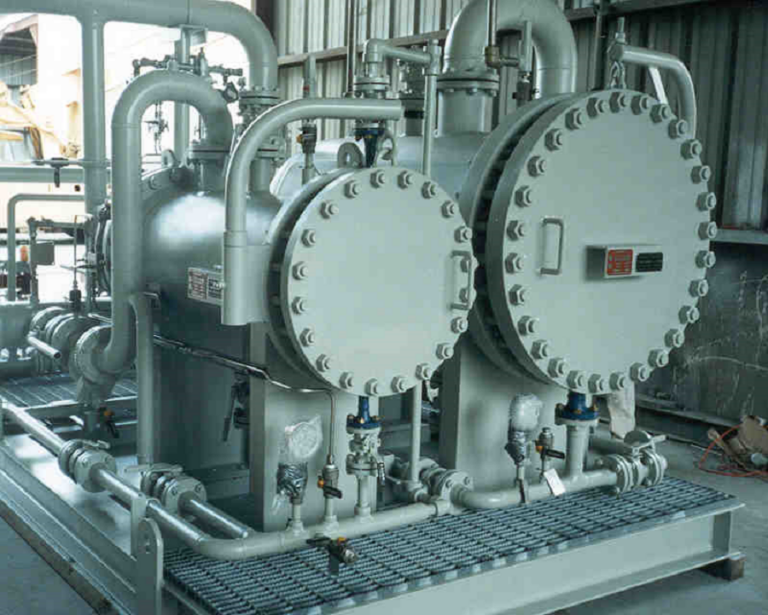

CPI SEPARATORS

CPI (Corrugated Plate Interceptor) separators are predominantly used in the separation of free oil from produced or effluent water or suspended solids for oily water treatment in an (Oily Water System) (OWS).

INDUCED GAS FLOTATION

The most effective performance solution to tough produced water treatment problems is IGF process that has both the oil water separator and the IGF.

The IGF can be either a vertical or a horizontal vessel.

WALNUT SHELL FILTERS

Nutshell filtration is applied to purify refinery wastewater, steel mill direct spray and caster water, quench water in ethylene cracking plants, copper concentrate decant and cooling water.

DEOILERS

Hydrocyclone based process systems, are the most cost-effective solution for

tough produced water treatment clean up. Located directly downstream on the

water outlet of the production separator, and upstream of the water level control

valve, these systems operate in a proportional “pressure ratio” control manner.

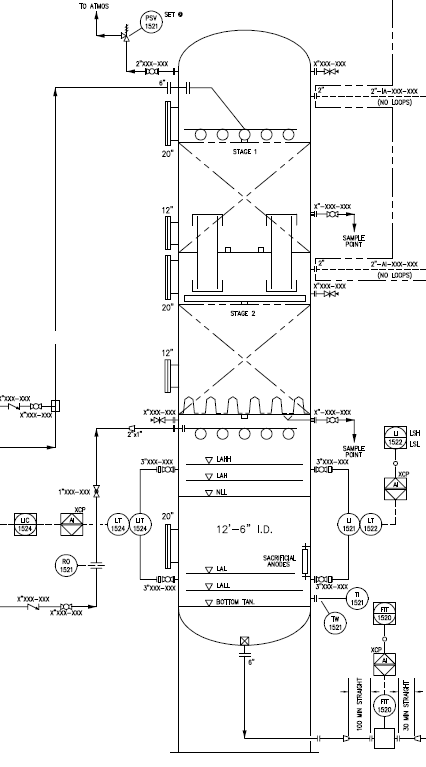

DEAERATION

Can be accomplished in a packed tower using a vacuum system to pull a

vacuum on the tower, thereby causing the water to flash, with the water

vapor acting as the scrubbing gas. This is the second most economical

method of deaeration.

BULK PLANTS

Flotation combined with Nutshell filtration is applied to clean oily wastewater less than 8 ppm in the effluent.