Our research activities have always focused on the properties of filtration surfaces, which need to be suitable for the contaminant to be removed from water. That’s why we have implemented Nanotex™ technology (registered trademark) based on nanotechnologies applied to surfaces.

All our polyester tissues are available in the Nanotex™ technology version:

OILREPELLENT™

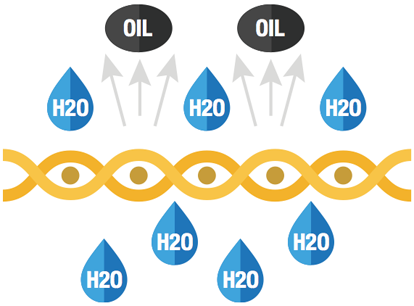

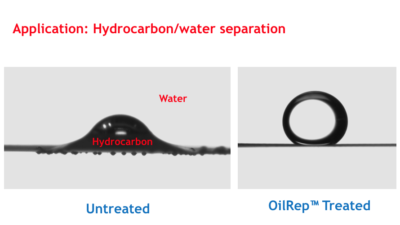

Using Nanotex™ OilRep™ technology, the tissue takes on a super hydrophilic properties.

The oil particles and hydrocarbons are rejected by the filter surface with negative Z potential, while the water is free to pass.

NO FOULING

KILLBAC™

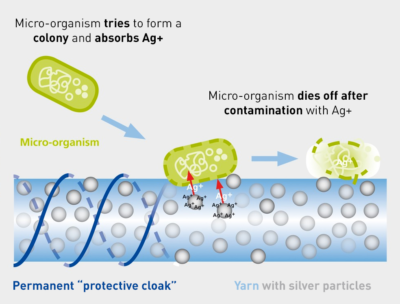

Using Nanotex™ KillBac™ technology, you can obtain a special antibacterial fabric.

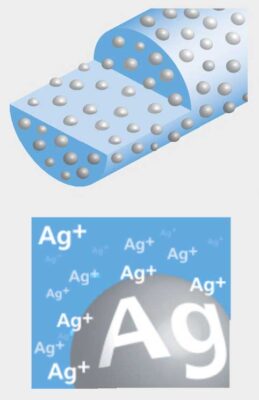

The silver particles integrated in the polymer are a fixed component of the yarn. This minimizes the breakdown of silver particles through thermal and mechanical stress. It also achieves a good repository effect.

The yarn generates a permanent “protective cloak” and inhibits or prevents any microbial or bacterial regrowth.

Micro-organism tries to form a colony and absorbs Ag+. Micro-organism dies off after contamination with Ag+.

· The use of additives such as chlorine, anti-algae and flocculants can be reduced or completely discontinued.

· Reduces carbonate hardness (calcium and magnesium ions) and the amount of chlorine and lead in water.

· Prevents the formation of a biofilm on water.

· Minimizes or completely prevents odor formation.

· Increases the shelf-life of water in closed circuits or storage systems.

TELL US ABOUT YOUR PROJECT