SELF CLEANING FILTERS

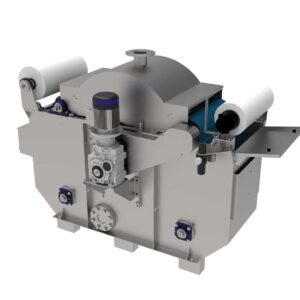

ABF FILTER

The ABF is a compact, under-vacuum filter that use a filter support made of non-woven disposable roll.

The filter is composed of two tanks. The internal one is dedicated to the dirty filtration, while the external one contains the filtrate and/or the overflow.

The dirty fluid pours into the upper compartment of the tank, passes through the filtering paper, which retains the contaminant contained in the liquid, and the resulting purified liquid flows in the tank underneath.

The layer of dirt retained by the paper is called “cake”. It improves the filtering process.

The compartment containing the clean water, is part of the first tank. It is maintained under depression using a suction pump for the permeate.

The vacuum in the filtration chamber is between (-0,2 ÷ -0,4bar)

Thanks to the mechanical seal obtained by filter tissue and the rotating discs, it is possible to maintain in vacuum the filter paper, thus increasing considerably its life cycle.

The increase in particles in the filter medium causes the increase in the fluid level inside the first tank. By means of a dedicated controller with an inverter, this increase of the fluid level generates the wrapping of the filter paper.

The ABF filtration system can be implemented with the OilRepellent filter.

Applications:

- Food & Beverage

- Steel Industry

- Petrochemicals

- Pulp & Paper

- Reuse Water

- Irrigation

- Intake Water

- Drinking Water

- Wastewater

- Intake seawater

- EGCS scrubber systems (DeSox)

- Bilge water

- Grey water

- Dry bilge

- Ultrafiltration

- Protection systems of the desalination or cooling plant

- Sea Water – protection systems of the desalination or cooling plant and ultrafiltration

- Fish farms – process water, UV disinfection system

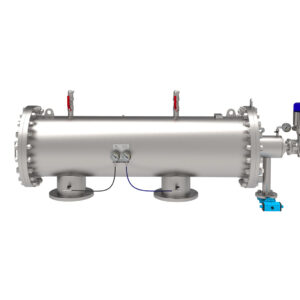

ABR FILTER

The automatic self-cleaning filter with brushes for the prefiltration of surface and process water containing not-colloidal suspended solids.

• Stainless steel housing and filter cartridge

• Interchangeable screens with several filtration degrees

• Ecomonic and robust choice for automation of filtration

• Low inlet pressure requested

ABR filters are automatic filters with a set of brushes mounted on a

rotating shaft, driven by an electric motor.

ABR filters can support flow rates of up to 1870 m³/h (8233 US gpm) with several sizes of screens up to 19800cm², with several screens covering the range of filtration degree between 3000 and 100 µm and with different range of inlet/outlet connections between 2″ and 16″.

Applications:

- Food & Beverage

- Chemical

- Steel Industry

- Fish farms – process water, UV disinfection system

ABR170 FILTER

ABR 170 filters are automatic self-cleaning filters with high efficiency due to the continuous filtration process and the low cleaning water consumption.

ABR 170 filters are automatic filters with suction scanning and brush self-cleaning mechanism, driven by an electric motor.

Thanks to flexible mechanism scanner, ensuring adherence to the screen, this filter has high a cleaning efficiency.

The body and the covers of the filter are made in 254SMO, designed for filtration of sea water discharged from the DeSox tower.

The multi-layer polyester filtering cartridge is composed of polyester (PETP) filter tissue fitted between two tubular support screens of SAF2205.

This multi-layer system allows to have a filtration range from 800 µm to 25 µm and allows to protect the filtering tissue from wear caused by passage of suction pads.

Special suction pads ensure the complete cleaning of the screen with minimum water consumption and without stopping the filtration process.

These special suction pads are supplied with integrated brushes that allow to improve the cleaning of filtering screen.

Applications:

- Intake seawater

- EGCS scrubber systems (DeSox)

- Bilge water

- Grey water

- Dry bilge

- Ultrafiltration

- Protection systems of the desalination or cooling plant

ABV FILTER

The automatic self-cleaning filter with double cleaning system.

High efficiency due to the combined action of brushes and vacuum pads, particularly suitable for river water.

• Multi-layers screens with several filtration degrees

• No interruption flow during the cleaning cycle

• Economic and robust choice for automation of filtration

• Very simple and reliable cleaning mechanism with special pads with brushes

ABV filters are automatic filters equipped with a double cleaning system, which allows the filter to be used even in the presence of coarse suspended solids.

Thanks to this double system, this filter has a high cleaning efficiency: first, the brushes remove the most coarse solids from the filtering tissue, then, through the opening of the drain valve on the cover, the suction scanner effect is generated, in which the pads suck the smaller solids.

ABV filters can support flow rates of up to 1850 m³/h (8145 US gpm) with five sizes of screens up to 19800 cm², with several multi-layers screens covering the range of filtration degree between 1000 and 10 µm and with different range of inlet/outlet flanged connections between 2″ and 16″

Applications:

- Food & Beverage

- Chemical

- Steel Industry

- Power Generation

- Petrochemicals

- Electronics

- Pharmaceutical

- Pulp & Paper

- Automotive

- Reuse Water

- Irrigation

- Intake water

- Drinking water

- Agriculture

- Protection systems of the desalination or cooling plant

- Ultrafiltration

- Fish farms – process water, UV disinfection system

AMA FILTER

Microfiltration up to 1 micron with automatic cleaning.

• Plated multilayer cartridge AMC with large filter area

• Efficient cleaning with pressurized nozzles

• Multi-cartridge solution

• Available with multi-body filters for high flow rates.

AMA filters are self-cleaning filters with automatic cleaning of AMC filter cartridges with pressurized nozzles. The filtration is from inside to the outside; the center shaft with nozzles proceeds to clean the cartridges for clogging achieved (thanks to the differential pressure switch) or at preset time, managed by a controller. An external source of pressurized clean water supplies cleaning nozzles; the drain of the washing water is by gravity.

The reinforced fiberglass body encloses up to two 20” cartridges, with a filtration range of 25 to 1 μm, and it can have 3” to 8” flanged input / output connections.

All materials used are compatible with drinking water and sea water resistant.

Control systems are available suitable for the single filter and for the more complex filtration batteries, in the various voltage versions, single-phase and three-phase, characteristics of the various countries.

Applications:

- Petrochemicals

- Electronics

- Pharmaceutical

- Intake seawater

- EGCS scrubber systems (DeSox)

- Bilge water

- Grey water

- Dry bilge

- Ultrafiltration

- Protection systems of the desalination or cooling plant

- Protection systems of the desalination or cooling plant Ultrafiltration

Avb FILTER

The automatic self-cleaning filter with high efficiency due to the continuous filtration process and the low cleaning water consumption.

• Multi-layers screens with several filtration degrees

• No interruption flow during the cleaning cycle

• Minimum cleaning water consumption

• Very reliable and efficient cleaning mechanism with suction scanner with brush

AVB filters are automatic filters with suction scanning with brush self-cleaning mechanism, driven by an electric motor. This tecnology ensure execellent cleaning even with reduced pressure at the filter inlet, thanks to flexible mechanism of scanner, ensuring adherence to the screen, this filter has high cleaning efficiency.

AVB filters can support flow rates of up to 1850 m³/h (8145 US gpm) with seven sizes of screens up to 19800 cm², with several multi-layers screens covering the range of filtration degree between 1000 and 10 µm and with different range of inlet/outlet flanged connections between 2″ and 16″.

Applications:

- Chemical

- Electronics

- Pulp & Paper

- Automotive

- Intake seawater

- EGCS scrubber systems (DeSox)

- Bilge water

- Grey water

- Dry bilge

- Ultrafiltration

- Protection systems of the desalination or cooling plant

- Protection systems of the desalination or cooling plant Ultrafiltration

- Process water

- UV disinfection system

Avc FILTER

The automatic self-cleaning filter with high efficiency due to the continuous filtration process and the low cleaning water consumption.

• Multi-layers screens with several filtration degrees

• No interruption flow during the cleaning cycle

• Minimum cleaning water consumption

• Very reliable and efficient cleaning mechanism with suction scanner

AVC filters are automatic filters with suction scanning self-cleaning mechanism, driven by an electric motor. Thanks to flexible mechanism scanner, ensuring adherence to the screen, this filter has high cleaning efficiency.

AVC filters can support flow rates of up to 1850 m³/h (8145 US gpm) with seven sizes of screens up to 19800 cm², with several multi-layers screens covering the range of filtration degree between 1000 and 10 µm and with different range of inlet/outlet flanged connections between 2″ and 16″.

Applications:

- Plastic & Textile

- Food & Beverage

- Chemical

- Steel Industry

- Power Generation

- Petrochemicals

- Mining

- Electronics

- Pharmaceutical

- Pulp & Paper

- Automotive

- Water reuse

- Intake water

- Drinking water

- Irrigation

- Intake seawater

- EGCS scrubber systems (DeSox)

- Bilge water

- Grey water

- Dry bilge

- Ultrafiltration

- Protection systems of the desalination or cooling plant

- Protection systems of the desalination or cooling plant Ultrafiltration

- Fish farms – process water, UV disinfection system

AvC-FRP FILTER

The automatic self-cleaning filter with high efficiency due to the continuous filtration process and the low cleaning water consumption.

• Multi-layers screens with several filtration degrees

• No interruption flow during the cleaning cycle

• Minimum cleaning water consumption

• Very reliable and efficient cleaning mechanism with suction scanner

AVC filters are automatic filters with suction scanning self-cleaning mechanism, driven by an electric motor. Thanks to flexible mechanism of scanner, ensuring adherence to the screen, this filter has high cleaning efficiency.

AVC filters can support flow rates of up to 220 m³/h (969 US gpm) with screens up to 7200 cm2, with several multi-layers screens covering the range of filtration degree between 2000 and 10 µm and with 6” inlet/outlet flanged connections.

Standard controller:

• AWC Basic controller (differential pressure and/or preset time and/or manual start, IP56, 4DI, 2AI, 4DO, Graphic Display 1×24 digit)

Available 2 controller:

• AWC FULL controller

• AWP FULL controller

Applications:

- Intake seawater

- EGCS scrubber systems (DeSox)

- Bilge water

- Grey water

- Dry bilge

- Ultrafiltration

- Protection systems of the desalination or cooling plant

- Protection systems of the desalination or cooling plant