Our Solutions

We design, build and test the equipment according to the highest standards and quality control procedures.

We use modern three-dimensional modeling techniques to provide robust solutions with minimum operational and maintenance requirements.

PRODUCTS

expectations of our customers in all sectors

Wastewater Products

SCREENING EQUIPMENT

Wastewater screening involves a mechanical-physical process aimed at removing solids and organic substances from the wastewater. Located upstream of wastewater plants, this equipment removes materials and substances which, due to their nature and size, may damage the equipment and jeopardize the efficiency of downstream treatment processes.

COMBINED UNITS

We design and develop combined units for separating sand and greasy oils from wastewater.

All products are designed to last over time and aim to facilitate the operator as much as possible. For this reason, our company has always paid special attention to detail to deliver sturdy and durable products.

GRIT EQUIPMENT

We offer a wide range of grit equipment, sand and grit separators and washers, the ideal solution for removing sand and grit during wastewater treatment processes.

Desanding and de-oiling are fundamental steps in primary wastewater operations. For this purpose, our company has developed a range of advanced sand treatment systems using cutting edge technology.

SCREW & BELT CONVEYORS

Screw conveyors are designed to transport dewatered sludge, sands and screenings for wastewater treatment applications.

This equipment conveys solid, semi-solid, and granular or powder phase out of the treatment plant up to the collection point.

DOSING SYSTEMS

Our dosing stations are specially designed to produce basic solutions or solutions using synthetic flocculants (polyelectrolytes), with the purpose of achieving effective colloidal substance separation.

DISSOLVED AIR FLOTATION (DAFs)

Flotation units are designed to carry out chemical-physical wastewater treatments. The air dissolved into the system provides for solid / liquid separation. The air injected into the water causes the formation of bubbles that come into contact with the suspended particles that rise to the surface.

PEN STOCKS

Penstocks are commonly used in water management systems to control the water flow in rivers, channels, intake structures and water reclamation facilities. Penstocks are also used across a wide range of applications, in particular, in the field of civil and industrial wastewater treatment and depuration.

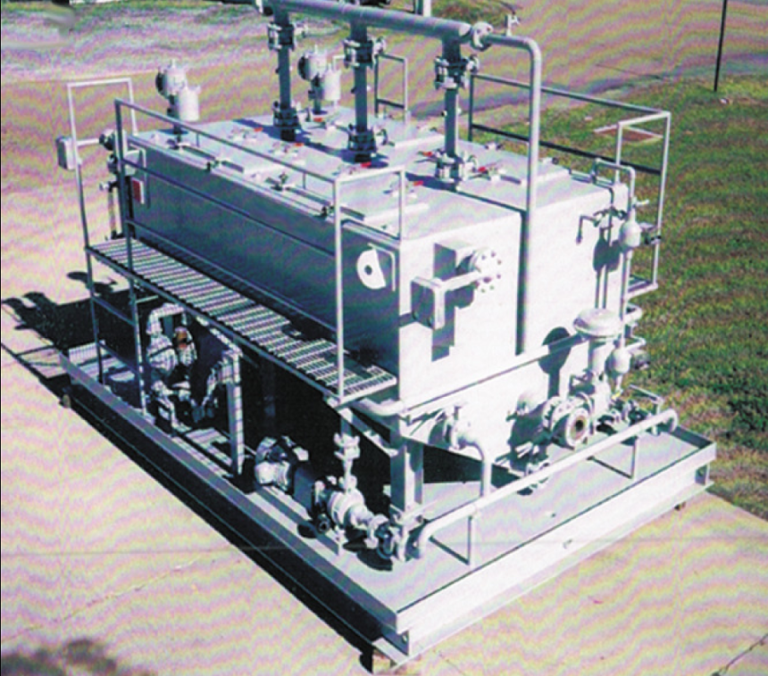

PACKAGE PLANTS

Static bar screens are designed to clear influent water of suspended particulate solids that may settle in subsequent sections of the plant. We guarantee that our screens are made of sturdy material, resistant to atmospheric agents.

DIFFUSERS

Coarse bubble diffusers are most commonly used in secondary treatment applications, where substances such as sediment and carbonate can build up quickly. The growth of these materials can be detrimental to fine bubble diffusers, which have smaller openings that plug more easily.

CHAIN & FLIGHT SYSTEMS

Our plastic chain scraper is a proven product that has been on the market for more many years. We offer you reliability and consistency with our well-engineered chain scrapers.

DOSING STATIONS

Our polyelectrolyte preparation and dosing stations are specially designed to produce basic solutions or solutions using synthetic flocculants (polyelectrolytes), with the purpose of achieving effective colloidal substance separation.

FLOCCULATORS

Our company manufactures both static and dynamic flocculators for sludge mixing applications. We offer both cylindrical stainless steel tanks and PVC serpentine coils.

Water Products

INCLINED PLATE SETTLER

Inclined Plate Settlers (IPS) are used to accelerate precipitation of solids in water and are optimized to achieve maximum performance during the clarification phase.

CHAIN & FLIGHT SYSTEM

Our plastic chain scraper is a proven product that has been on the market for more than 40 years. We offer you reliability and consistency .

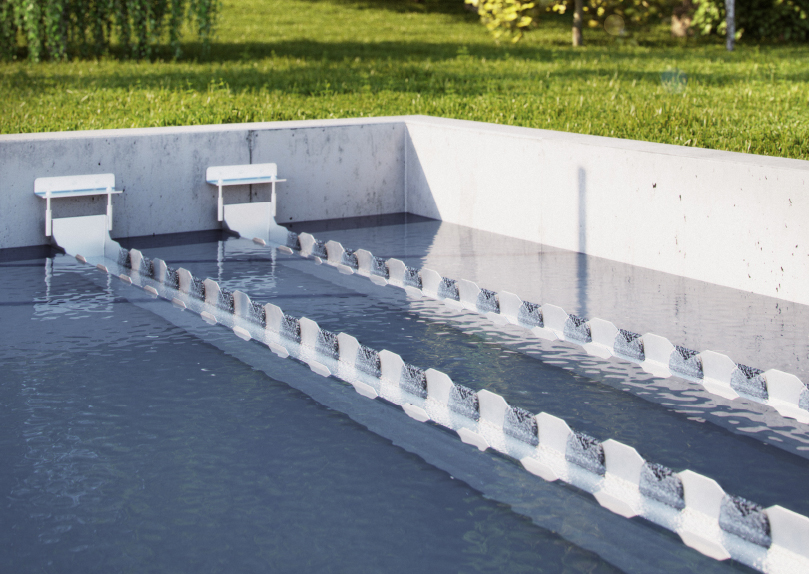

OVERFLOW WEIRS

Overflow weirs for surface water removal from rectangular clarifying tanks are made of stainless steel with Thompson v-notches.

Produced Water Products

OIL WATER SEPARATORS

Designed according to API 421, Oil/Water Separators combine state-of-the-art separation, skimming and sludge transport technologies into a highly efficient primary oil separation device.

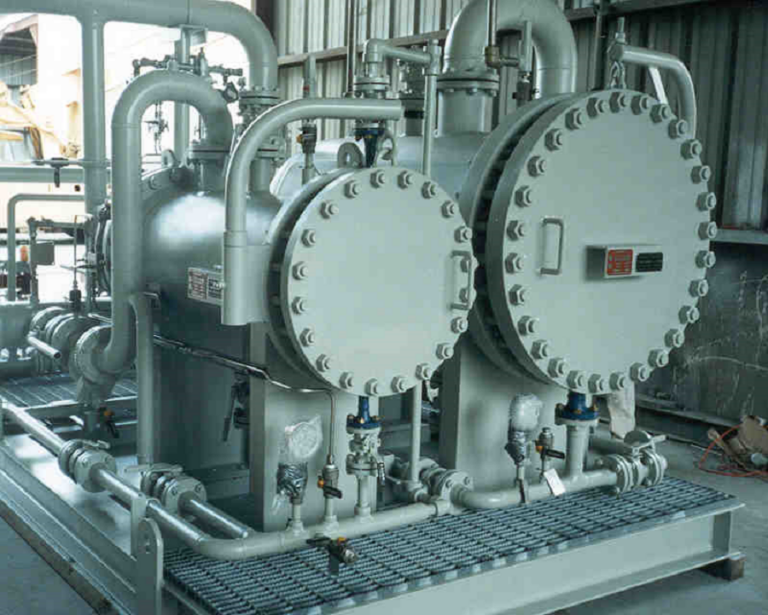

CPI SEPARATORS

CPI (Corrugated Plate Interceptor) separators are predominantly used in the separation of free oil from produced or effluent water or suspended solids for oily water treatment in an (Oily Water System) (OWS).

INDUCED GAS FLOTATION

The most effective performance solution to tough produced water treatment problems is IGF process that has both the oil water separator and the IGF.

The IGF can be either a vertical or a horizontal vessel.

WALNUT SHELL FILTERS

Nutshell filtration is applied to purify refinery wastewater, steel mill direct spray and caster water, quench water in ethylene cracking plants, copper concentrate decant and cooling water.

DEOILERS

Hydrocyclone based process systems, are the most cost-effective solution for

tough produced water treatment clean up. Located directly downstream on the

water outlet of the production separator, and upstream of the water level control

valve, these systems operate in a proportional “pressure ratio” control manner.

DEAERATION

Can be accomplished in a packed tower using a vacuum system to pull a

vacuum on the tower, thereby causing the water to flash, with the water

vapor acting as the scrubbing gas. This is the second most economical

method of deaeration.

BULK PLANTS

Flotation combined with Nutshell filtration is applied to clean oily wastewater less than 8 ppm in the effluent.